🌍 Getting current on kelp processing with Macro Oceans

The synthetic bio startup sees an upswell of seaweed applications beyond the food industry

Digging into Kula Bio’s microbial fertilizer future

100 years ago, the world was on the brink of mass starvation. The labor intensive agricultural system could not keep pace with the booming global population. Feast or famine hung in the balance of supplies of manure and compost, saltpeter, and guano (literally batshit). Two extraordinary scientists rose to the call and developed the Haber-Bosch process for the synthesis of artificial fertilizers. However, Haber and Bosch’s scientific genius came at a price that the world is still paying.

A few years after their discovery, the Haber-Bosch factory employed 35,000 workers and occupied 3 square miles (and was also the bullseye of US bombers during WWII). In addition to fixing nitrogen to provide food for a growing population, the Haber-Bosch process was used to make gunpowder and explosives that killed millions and fueled the rise of Hitler. Both complex scientists died disillusioned and disgraced - yet their eponymous nitrogen fixation process remains a foundation of modern industry upon which - quite literally - the world population rests. (Get this: 50% of the N found in the tissue in your body originated from the H-B process.)

A century later, the world faces another apocalyptic threat - climate change - in which the Haber-Bosch process plays another leading role. But first, a quick science lesson.

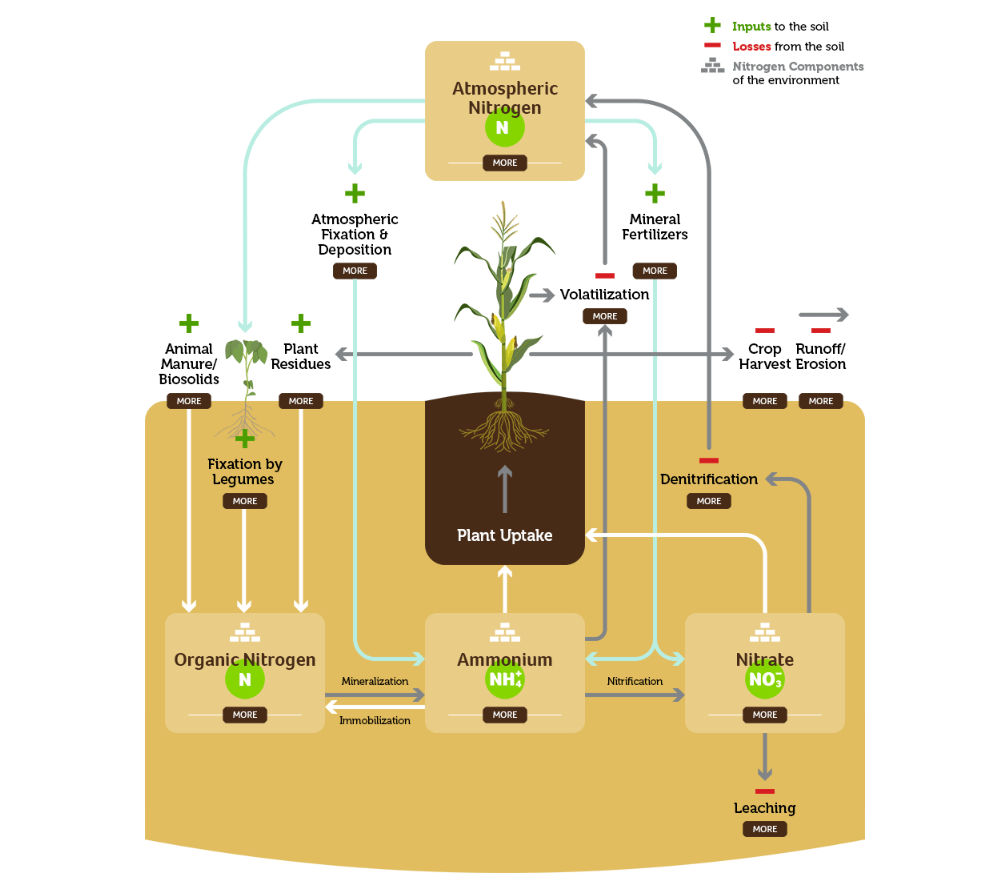

Remember NPK? Nitrogen (N), Phosphorous (P), and Potassium (K) are the three essential nutrients that crops need to grow. Of the three, nitrogen is the most limiting to crop production since plants can’t utilize atmospheric nitrogen. Although nitrogen makes up ~78% of the air we breathe, it’s inert in N2 form and unavailable to plants without fixation into chemical compounds like NH3 (ammonia). Shown in the graphic above as green plus sign flows, N2 → NH3 is given a helping hand from fixation processes like lighting, legumes, soil microbes, and the Haber-Bosch process. Different chemical combinations form common nitrogen fertilizer types including Urea, Ammonia, Ammonium Sulfate, Ammonium Nitrate, and Calcium Ammonium Nitrate. N fertilizers make up ~60% of total fertilizer volumes, equating to a massive $100b+ global market.

A majority of synthetic nitrogen fertilizer is produced using the Haber-Bosch process, which captures nitrogen from the air and combines it with hydrogen derived from natural gas to produce ammonia. The H-B fertilizer production process alone makes up 1.4% of all global GHG emissions. However, if you also factor in the emissions from distribution and (mis)application of synthetic fertilizer, arguably almost 7% of all global GHG emissions can be traced to the synthetic fertilizer supply chain. With ~300 massive plants across the globe, nitrogen fertilizer is distributed through a centralized supply chain incurring significant transportation and storage costs. About half of the nitrogen fertilizer applied is lost as runoff or N2O, a greenhouse gas with 300x the global warming potential of CO2.

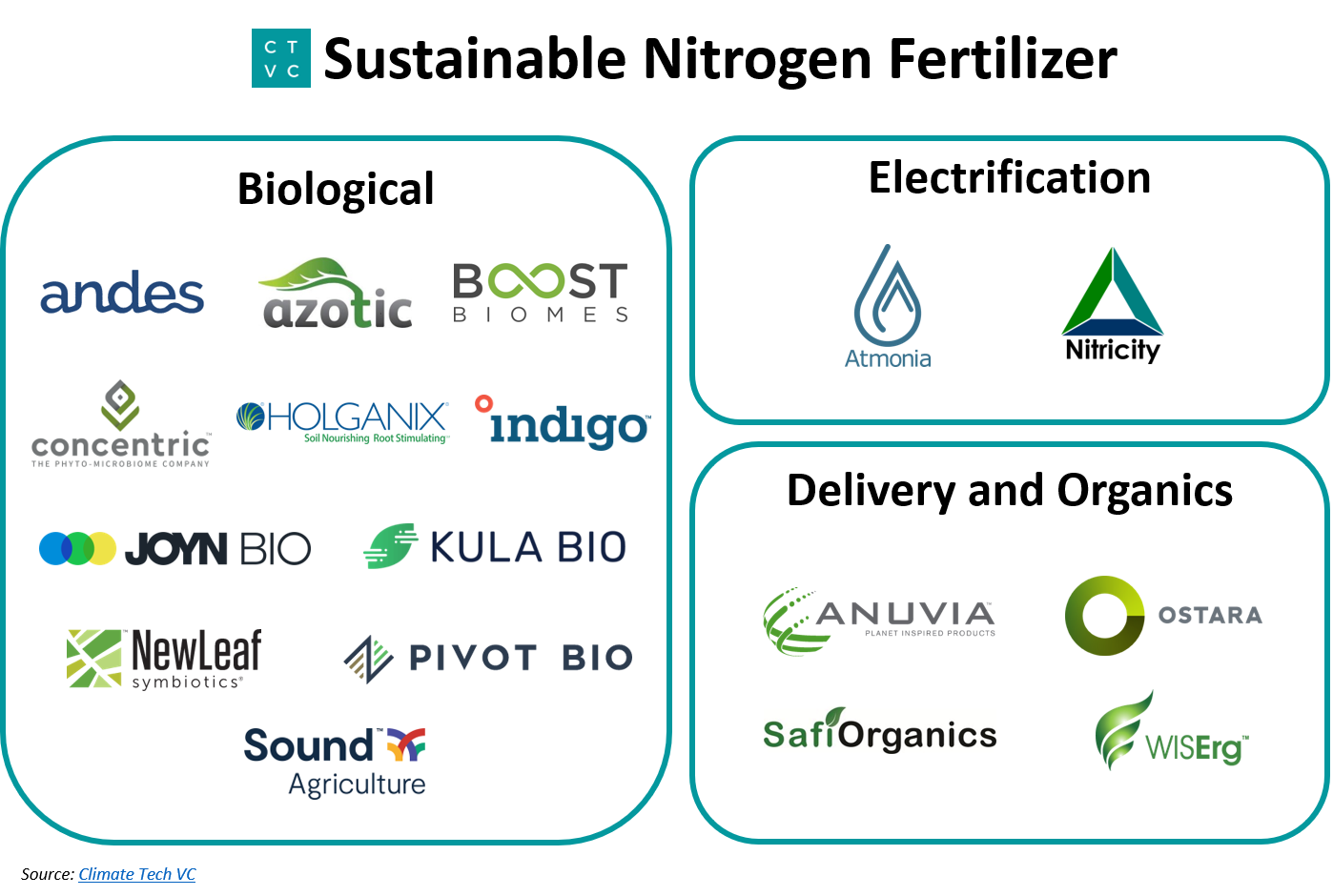

A bevvy of startups are out to disrupt the 100 year old nitrogen fertilizer process, through a series of approaches.

🧫 Biological: microbial N fixation through either 1) consortiums of concentrated beneficial microbes, or 2) isolated and boosted select species

⚡ Electrification: using renewably-sourced electricity to power N fixation, at the source

🌱 Delivery and Organics: nutrient recovery, efficient uptake mechanisms, decentralized production

We caught up with Bill Brady, CEO of Kula Bio and veteran clean energy executive from Monolith Materials and Mascoma Corporation. Bill shared the news about Kula Bio’s announced $10m Seed fundraise, and divulged details on the company’s innovative approach to biofertilizer R&D, manufacturing, and sales.

Big disclaimer: Sophie helped start Kula Bio in 2018 and remains an advisor to the business.

Let’s kick off - what’s the origin story of Kula Bio?

It all started in the lab of Professor Dan Nocera, who had been studying the idea of funneling solar energy through microbes to do interesting things. At first he focused on using fuels and chemicals (like with the Bionic leaf), but then turned to using that energy to charge microbes to fix nitrogen - one of the most biologically energy intensive processes. So Dan, his postdocs, and synthetic biologist Pamela Silver mixed up the microbes in the lab, did some initial experiments on radishes. And - doggone it! - these super-charged nitrogen-fixing microbes could really deposit a lot of nitrogen. And we took it as a company from there.

Fascinating. What’s the scientific process from microbe to nitrogen production?

It’s twofold: the right microbe that can do the nitrogen fixation, and the energy storage component. On the microbe front, Dan selected a naturally occurring Xanthobacter microbe that wasn’t genetically modified. In our Kula Bio process, we simply fatten up the microbe with energy like a bear going into hibernation, so that it can live up to 2.5 weeks in the soil - compared to the typical couple of hours.

A really phenomenal attribute of this particular microbe is that it's very industrially robust. Many of the other microbial approaches in fertilizer are very interesting, but they operate on the sensitive edge of science. Likewise, the energy storage component is really important. Once we reproduce the microbe to the desired density in our bioreactors, it metabolizes hydrogen, carbon, and oxygen and has a natural ability to make this energy-storing material. The bioreaction is a two step process of 1) driving up the microbial density and 2) fattening up the microbe with energy. The end product kind of looks like orange juice and can be applied directly from our reactor into the soil.

What inputs go into the reactor?

I was attracted to this technology because of the simplicity of the inputs. It’s water, microbes, a nutritional salt mix, and air. Then you add a little bit of energy into the reactor to get it done, and the end product is carbon negative by the time it goes into the soil.

Why are microbes an interesting approach to improving the sustainability of fertilizer?

There are millions of microbes in the soil, most of which are beneficial. Some biofertilizer approaches isolate the most beneficial ones, and concoct a consortium of those as a biostimulant. Other approaches take microbes that do a specific job, like how we're using a natural nitrogen fixer, and give them an ability to do it better.

Another basic dynamic at play with using synthetic nitrogen is that your soil quality and organic matter deplete over time. So, if you treat the soil with organic and biological sources instead, the soil quality itself will go up over time.

What challenges have microbial approaches faced so far, and how is Kula Bio trying to solve them?

Most microbial approaches face an energy bottleneck problem, which fundamentally limits nutrient delivery to an incremental 5-10% improvement. But farmers aren’t willing to take the risk of adopting a new product for a marginal improvement.

Kula Bio’s novel approach addresses that energy bottleneck problem. In all of our commercial trials, we've demonstrated the ability to replace between 50-80% of synthetic nitrogen at equivalent yields. We’re also plant agnostic. While many other approaches design microbes for particular plant-soil combinations, we simply take nitrogen from the air and deposit it in the soil so that any type of plant can use our fertilizer.

What’s the current agricultural fertilizer supply chain? How does Kula Bio fit?

The fertilizer value chain varies by type of farming operation and geography. Big volume row crop farmers buy tank loads of fertilizer directly from factories and small to medium farmers rely on a well-entrenched retail network of input companies like Nutrien or Wilbur-Ellis that have strong regional presences and bundle products and services for farmers.

When farmers have questions about what fertilizer to buy or new products to try, they talk to crop advisors or agronomists. Many of the retail suppliers have excellent agronomists on staff. Farmers have been working with these folks for generations and share a deep trust.

Part of our job as a startup getting into the market is to make sure that we prove to those agronomists that our product works, in order to build farmer trust. For any new entry into ag, farmer adoption is the hardest challenge.

What product characteristics do farmers care about when considering adopting a new product like Kula Bio?

So again, it depends what type of farmer you're talking about. Organic and regenerative growers pay a high price per pound of nitrogen. Our product can be really competitive with that. Also, those farmers have to put the nitrogen source down 6-9 months prior so it has time to decompose, whereas our microbes start working right away.

There are two primary benefits for big row crop growers. One is we don't produce runoff nearly as much as synthetic fertilizer does. The second factor is soil quality. Farmers care a lot about the quality of their soil, and if they treat it with environmentally beneficial products, their soil quality and crop yields go up and input needs go down over time.

The winning combination is something that works as effectively as synthetic fertilizer without all the negatives. Farmers are not going to give up yield nor pay a significant premium just because it's environmentally friendly.

How does Kula’s product perform from a carbon emissions perspective?

We’re better on both carbon avoidance and sequestration. Our natural process avoids Haber Bosch carbon emissions, but also sequesters carbon inherently as part of the energizing process. Like everyone else, we’re currently trying to work through the complexities of carbon measurement, verification, legislation, etc. in order to expand that side of our business and potentially develop another source of revenue generation for farmers.

What is Kula’s go to market strategy and traction so far?

We've had a significant number of trials on commercial farms, and demonstrated really solid results. Our trials have been done across both produce and row crops, with particularly interesting results in high value crops like tomatoes and berries. Those farmers are facing some of the strictest nitrogen restriction regulation coming down the pike, so there's been a lot of excitement in those segments. We’ll continue these trials into this year and continue to progress on our bio processing, quality, and overall capacity.

You just announced a $10m Seed round from investors like Collaborative Fund, Lowercarbon Capital, The Nature Conservancy, and the Grantham Foundation. Congrats! What’s next?

We were fortunate to have a pretty diverse set of funds participate from our existing investors, agtech-specialists, and carbon-focused VCs. We were particularly excited to have The Nature Conservancy and the Grantham Foundation's Neglected Climate Opportunities Fund step in, since they’re very focused on conservation. To get their recognition and investment was really key to us.

Our long-term vision is to develop a platform approach energizing beneficial microbes to do their job longer and better. We happened to pick nitrogen first, and we'll eventually move to phosphorus and other ag and non-ag applications over time as well.

Interested in getting your hands dirty seeding the future of sustainable agriculture? Bookmark Kula Bio’s careers page where they’ll soon be hiring for a number of R&D roles.

In other news, we’re taking a Memorial Weekend break this upcoming Monday, but expect to see us back in your inbox next Friday 🌎

Feel free to send us new ideas, recent fundings, or general curiosities. Have a great week ahead!

The synthetic bio startup sees an upswell of seaweed applications beyond the food industry

A gut check on reducing bovine burps

The underappreciated role of carbon insets in decarbonizing Scope 3 supply chains